Automatic Plastic Bag Premade Doypack Pouch Filling and Sealing Packing Machine

Description

Basic Info.

| Model NO. | MR8-200RH |

| Application | Cleaning, Detergent, Drinks, Skin Care Products, Dairy Products, Hair Care Products, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning |

| Type | Filling and Sealing Machine |

| Forming Species | Bag Moulding |

| Forming Function | Filling, Seal |

| Driven Type | Mechanical |

| Material Type | Grain |

| Packaging | Bag |

| Packaging Material | Plastic |

| Weight | 1500kg |

| Filling Speed | 30-60 Bags /Min |

| Pouch Type | Three/Four-Side Sealed Bags, Stand-up Pouch |

| Power | 4kw |

| Material | SS304 |

| Max Filling | 2kg |

| Transport Package | Wooden Packing |

| Specification | 2200*1550*1410mm |

| Trademark | LINPACK |

| Origin | Zhengjiang |

| HS Code | 8422303090 |

| Production Capacity | 1000sets/Year |

Packaging & Delivery

Package Size 2700.00cm * 2300.00cm * 1700.00cm Package Gross Weight 1800.000kgProduct Description

Product Description:

Linpack A Multi-Function Automatic Solid/Granule/Graine Premade Pouch Packing Machine

Machine Parameter:

Model NO.: | MR8-200RH |

Pouch type | stand-up pouches, zipper bags,four/three side sealed bags |

Pouch Size | Width(mm): 80-210, Length(mm):100-300 |

Filling Volume | 10-2000g(Depend on type of products) |

Capacity(PPM) | 45-60 bags/ min, 25-40bags/min for zipper bags |

Package Accuracy | Error≤±1G |

Total power | 2.5KW(220V/380V,3PH,50HZ) |

Demension | 2000*2000*4000mm(L*W*H) |

Weight | 2275KGS |

Compress air requirement | ≥0.8m³/min supply by user |

Features and Characteristics | 1. incessant rotary vacuum system |

2. quick changeover | |

3. comply with the sanitation requirements of food processing machines | |

4. materials contact parts adopt 304 stainless steels | |

5. easy to operate | |

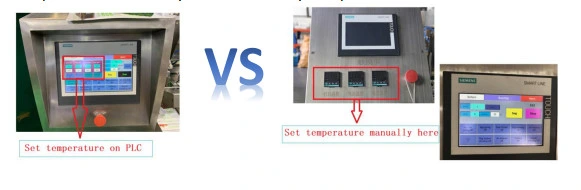

6. sealing temperature detection | |

7. the machine adopts PLC and POD(touch screen)electrical control system | |

8. friendly man-machine interface | |

9. high-quality sealing bag mouth | |

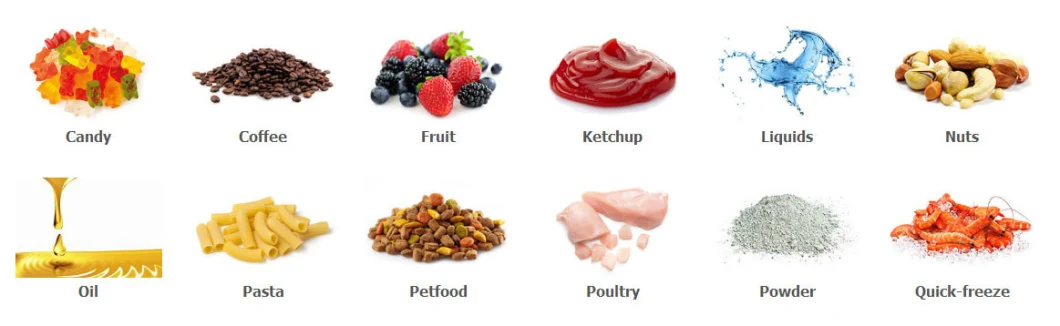

Application: | Block: chocolate, candies, cereal, biscuits, cakes, puffed food, etc. |

Granule: nuts, capsules, seeds, feeds, pesticides, fertilizers, etc. | |

Powder: seasoning, milk powder, washing powder, fine sugar,etc. | |

Liquid/sauce: detergent, juice, beverage, ketchup, jam | |

Pickles: carrots, etc. | |

necessary infos offered in inquiry | pouch type |

pouch size | |

filling material |

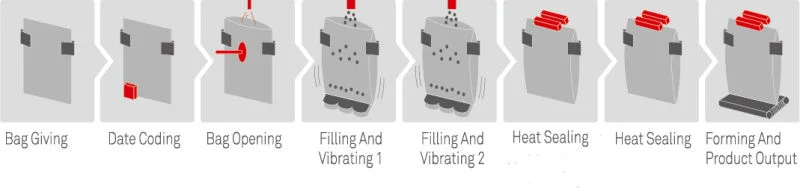

Main Function :

Pick up-Open-Fill -Seal preformed/premde Pouches for Products.

Applications :

1. Solid: Candy, chocolate, rock candy, cookies, cakes, peanuts, green beans, pistachios, nuts, cooked food, pickles, puffed food, daily necessities, etc.

2. Granule: MSG, chicken, sugar, melon seeds, nuts, capsules, granular medicines, seeds, feed, pesticides, fertilizers, chemical raw materials.

3. Powder: Spices, monosodium glutamate, salt, glucose, refined sugar, milk powder, detergent powder, pesticides, fertilizers, chemical raw materials, etc.

4. Liquid: Rice wine, soy sauce, rice vinegar, fruit juice, beverage, detergent, etc.

5. Thick liquid: Tomato sauce, peanut butter, jam, chili sauce, bean paste, etc.

6. Other materials can be bagged.

Suitable Pouch Type:

All type of heat sealable performed side seal bags, block bottom bags, zip-lock bags, stand-up pouch with or without spout etc.

Features and Characteristics:

1.Suitable pouches: All kinds of size premade pouches.

2.Easy to operate: PLC controller, HMI system, fault indication on the touch screen.

3.Easy to adjust: All working process in one station, more easily adjusting.

4.Frequency control: Speed can be adjusted by frequency conversion within the range.

5.High Automation: Unmanned in weighing and packing process, machine alarm automatically when failure.

Safety and Hygiene:

1.Machine alarm and stop when the inadequate air pressure.

2.Safety guards with safety-switches, machine alarm and stop when the safety guards are opened.

3.Hygienic construction, the product contact parts are adopted sus304 stainless steel.

4.Imported engineering plastic bearings, no need to oil, no contamination.

5.Oil-free vacuum pump, avoid the pollution of the production environmental.

What is the Advantage :

1.Adjust bag width: Manual adjusts the width of the clip,adjust clip size within 5 seconds

2.European Stanard Appearance: The advance designed ensures a stable performance and a equipment, and a lower rate of defective products

3.Temperature Control System: More easy to operate

Work Process | Station 1 Bag Feeding Station 2 Date Printing (option)and Open zipper bag Station 3 Open bag Station 4 Filling Materials Station 5,6,7 :Vibration,Air Removal,Nitrogen Filling,Close Zipper,Hole Punching,Heat Sealing Remark:No.5.6.7.Stations are based on customer requirements for adjusting. Station 8 Heat Sealing and Product Output |

Safey Measures | 1.no bag feeding, no filling and no sealing. |

Standard Equipment Part:

| 1. Date printer | 6. Temperature controller |

| 2. PLC control system | 7. Vacuum pump |

| 3. Pouch opening devices | 8. Frequency convertor |

| 4. Cylinder Cylinder | 9.Output system |

| 5. Magnetic valve |

Optional Parts :

| 1.Inkjet printer or laser printer | 2. Ultrasonic sealing |

| 3.Sombrero hole punching | 4.Electronic adjustment of pouch changeover |

Components List :

| Name | Brand | Origin |

| PLC | Siemens | Germany |

| Touch Screen | Siemens | Siemens |

| Vacuum Pump | ORION | Japan |

| Printer | Shenglong | China |

| Main Motor | Evergear | China |

| Proximoty Switch | OMRON | Japan |

| Bearing | IGUS | Germany |

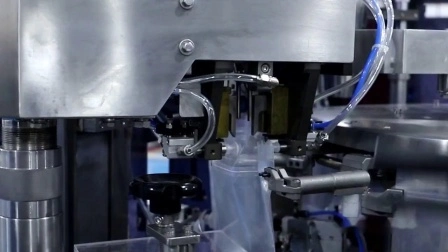

Detail Picture :

Certifications:

Company Information:

Our Value is : Innoative , Precise , Service, Faith

Our Mision:Be your first choice in pouch packing machine

Our Vission : Design and manufacture the most suitable and cost packing machine for the customers.

Linpack is manufacturing and trading company which is mainly engaged in the R&D, manufacture,marketing and service of plastic bag food packaging machine with more than 20 years in China.

The aim of Linpack is to give you a hand and assist you to solve your package problems with most suitable solution.

We are specialized in packing machine

1.Rotary pouch packing machine

2.Rotary vacuum packing machine

We provide professional packing solution and do a series of service from beginning to end

Our strength

1.Equipment make and assemble strictly in accordance with CE,ISO9001(certification) standard in our own CNC

2.20 years experience in packing industrial with good after-sale service group

3.Our professional team of research and development has got our own paten for invention

4.Professional sales and engineer team with 24 hours hot line to do design packing project, problem consulting,soultion.

5.Professional engineers group as after-service team can speak English and do overseas service.

We continually design new model and improve machines and solutions to satify different and stringent requirements from market.

Our professional pre-sales and after-sales service guarantee the complete satifaction of the equipments.Welcome to work with us to win a mutual benfit future.

FAQ:

QHow can I know your machine is designed for my product?

AYou can Send us product samples and Have a test on our Machine

QDo you test all your goods before delivery?

AYes,we have 100% test before delivery,and if you need,we can record a video about the test process of machine to you.

QDo you have any technical supports?

AYes,we have a profeesional team of engineers who owned many installation,debug and trainning experiences abroad,are available to service machinery overseas.

QHow can I know the machinery quality before shipping?

AWe will invite you visiting our factory to check the machines quality,and show the machine running to you in our factory.If you don't have time to vist we can record videos for you and try our best to meet your requirements.

Contact us

If any question , pls feel free to contact us .

Prev: Automatic Nut Pouch Food Doypack Multihead Weighing Weigher Premade Bag Granule Packing Doy Multi

Next: Automatic Potato Chip/Coffee Beans/Seeds/Rice/Granule/Fruit /Nuts /Snacks/Grain Vertical Stand

Our Contact